Good Laboratory Practice (GLP) compliance is an important aspect of research and development, as it creates trust and transparency between stakeholders in the process. When inspections occur, it is important to have all the necessary preparations in order, so the inspection runs smoothly, and the results are satisfactory.

In this blog, we will provide a comprehensive guide on how to prepare for a Good Laboratory Practice (GLP) inspection, as well as what to expect during and after your visit. With practical tips and advice, this guide will help you ensure a successful inspection and get the best possible outcome.

How to Prepare Personnel for the GLP Inspection

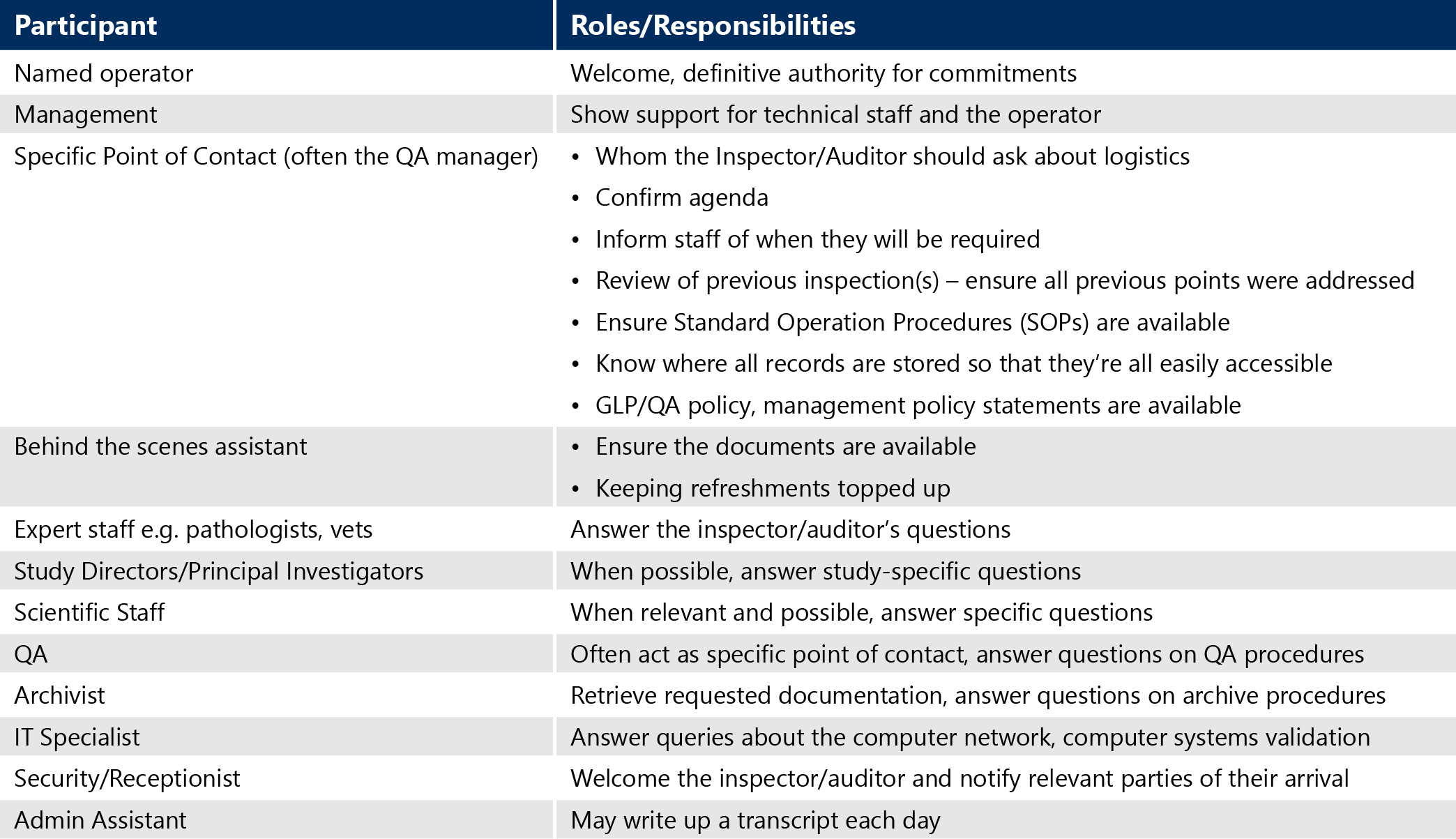

It is important to understand who will be involved, what roles they will play, and what is expected of them when preparing for a GLP inspection. Clearly defining roles such as a point of contact, management support, and expert staff, will ensure the inspection is carried out with minimal disruption.

The table below provides some suggestions, but it is not an all-inclusive list.

For a successful GLP inspection, it is important to ensure the availability of key personnel and systems or records. If key personnel are unavailable on the inspection day, the inspector should be notified in advance. Identifying appropriate representatives can be helpful and allow for training opportunities. It’s also important to note that a regulatory authority inspector(s) has full access to all parts of the GLP facility and its data and records, so other staff may need to interact with these individuals.

During inspections, the attitude of both the company and the inspector should be clear and courteous. As such, personnel should be trained beforehand on how to respond during an inspection, such as being polite and only answering the questions they understand.

Preparations for an inspection should be finalized in advance

The number of inspectors and type of inspection dictate the room layout needed, as well as any special protective clothing or footwear for certain visits. Lunch and refreshments should be provided, and any special dietary requirements should be checked beforehand.

Computer access should be decided in advance, with printing out requested information or having a staff member access it while the inspector watches being recommended, unless the inspector requests otherwise.

Inspectors may request documents such as policy documents, organization charts, SOP indexes, computer systems list and more. Companies can create an “audit pack” containing such information and hand it to the inspector at the start of the audit. It is important to ensure these documents are up-to-date and readily available, while taking care to protect confidential information relating to other clients.

Conducting the Inspection

When it comes to inspections in a testing facility, there are certain procedures that need to be followed.

Inspectors must be processed according to site regulations, which includes verifying their identity, providing emergency protocol details, issuing a security pass, and asking them to remove any prohibited items. Depending on the inspection, a test facility representative or QA will take the lead role.

It is also important to be aware of language barriers and provide an interpreter if necessary.

The inspection will start with the inspectors stating the objectives and scope of the inspection, and the host welcoming them and providing information about any organizational changes or policies. During the inspection, facility tours are essential, and inspectors will be assessing GLP control systems and reviewing relevant documents. Supporting documentation may also be requested, and inspectors may hold a debriefing at the end of each day to discuss any outstanding issues.

The inspection may be focused on GLP compliance or scientific aspects depending on the type of inspector, but it is important to be prepared and ensure that all areas and equipment are clean and orderly.

Post Inspection

The exit meeting is necessary to interview with personnel such as the test facility manager, relevant QA senior management and sponsor or test facility QA. During this meeting, inspectors will state their significant observations and any reporting requirements and timelines for responses. Notes should be taken to allow for rapid corrective action and correspondence with the inspectors. This also provides an opportunity to decide who should receive the audit report.

In addition to addressing the specific observations, it is also important to take a more holistic view of the facility’s operations and consider any wider implications of the inspection findings. This may involve reviewing standard operating procedures, training programs, or quality management systems to identify areas for improvement.

By taking a proactive approach to continuous improvement, facilities can ensure that they are operating at the highest level of quality and compliance.

Once the facility has addressed all the observations and implemented any necessary corrective actions, it is important to provide a timely response to the inspector’s report. This response should include a detailed description of the actions taken to address the observations, as well as any preventive actions that have been put in place to avoid similar findings in the future.

By providing a thorough response, facilities can demonstrate their commitment to quality and compliance, and may even be able to use the inspection process as a tool for continuous improvement.

Inspections provide assurance that work is compliant

In conclusion, hosting a GLP inspection can be a positive experience for both the host organization and the inspector. While it may require a significant amount of time and resources, it provides an opportunity to demonstrate the quality of services and facilities and can generate additional business. Facility inspections also provide reassurance that work is being conducted to an acceptable standard and can lead to recommendations for improvements. Moreover, inspections enable personnel to expand their network of contacts and provide valuable training opportunities.

While every inspection is unique, being prepared and flexible can help to ensure a successful outcome. Overall, a GLP inspection should be viewed as an opportunity to showcase the organization’s commitment to quality and compliance.

If you need additional support for Inspection Readiness, Mock Inspections, or general Compliance initiatives, contact MMS Quality & Compliance Team for how we can partner together at info@mmsholdings.com. Our experienced and knowledgeable team can help implemented processes to ensure you are inspection ready.

Learn more on our website.